Ensuring the purity and safety of our water supply is an essential component for all council areas. One aspect that plays a crucial role in safeguarding our water supply is the implementation of backflow prevention devices.

These devices protect our drinking water supplies from contamination by preventing potentially polluted water from reentering the system. They are a device that prevents contaminated water from flowing back into the system – hence, “backflow prevention device”!

In various residential, commercial, and industrial settings, backflow prevention devices are more than just an optional add-on; they are a legal requirement.

In this blog, we delve into the intricacies of backflow prevention devices, explore the different types available, and guide you through their essential maintenance practices to ensure your water remains clean and safe at all times (and to make sure you remain a law-abiding citizen)!

Backflow Devices Explained

A backflow prevention device is a crucial component of a plumbing system designed to protect potable (drinking) water supplies from contamination. Essentially, it acts as a one-way gate (or valve), ensuring that water flows only from the public water supply into a home or business, but not back the other way. This is critical because various conditions can create a sudden and unexpected reversal in the flow of water in a plumbing system, known as backflow (more on this later). This reversal can potentially draw contaminants such as chemicals, fertilisers, human waste, and other pollutants into the clean water supply.

There are various situations where contamination can occur, including within pipes that have direct access to the drinking water supply, connected auxiliary water sources, submerged inlets, by-pass arrangements, removable sections, and temporary devices. For instance, if a sprinkler system is connected to the home’s water supply, fertilisers and pesticides could be drawn back into the drinking water during a backflow event (obviously not what we want)!

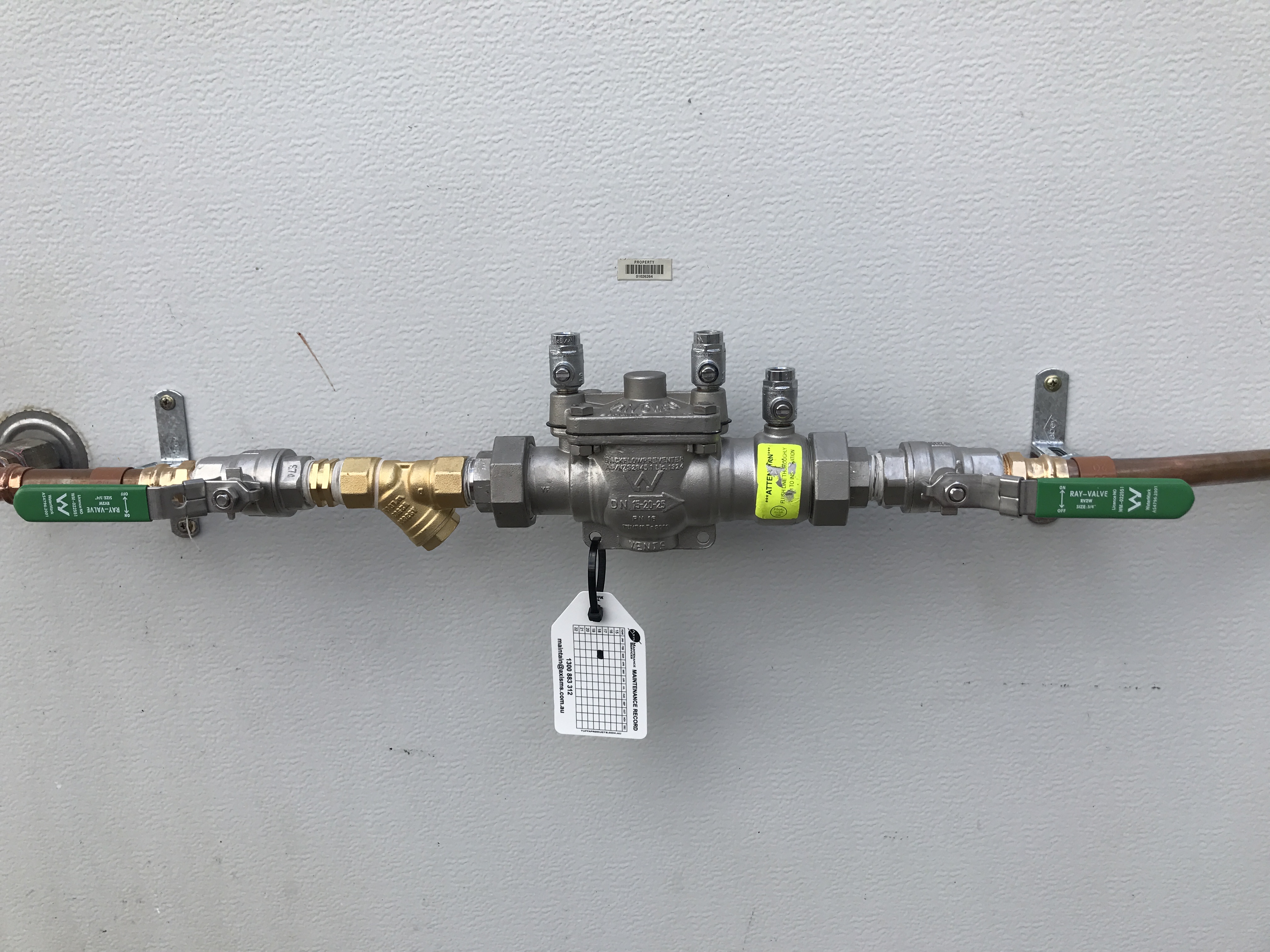

To counteract this risk, backflow prevention devices are installed at critical points within a plumbing system. These devices come in two main types: testable and non-testable.

Testable devices are designed with valves that can be checked regularly to ensure they are functioning correctly, while non-testable devices are simpler in design but cannot be tested for functionality.

The type of device required depends on the level of risk and the potential for contamination.

What Causes Backflow in Plumbing?

Backflow in plumbing is caused by two primary factors: backpressure and backsiphonage.

Backpressure occurs when the pressure in a non-potable system exceeds the pressure in the potable water supply line. When the pressure in the private system becomes greater than the public system, water can be pushed back into the main supply, potentially carrying contaminants with it.

Water heaters and boilers are frequent sources of backpressure in a plumbing system. As water heats, it expands, leading to increased pressure within the system. In such scenarios, a backflow preventer serves as a crucial barrier, preventing this water from contaminating the public water supply.

Backsiphonage occurs when there is a sudden reduction in the water pressure of the supply system, creating a partial vacuum that can draw water from a home or business back into the public water system.

This can happen during events like a water main break, during rapid withdrawal of water from fire hydrants, or when a supply line is shut down for repairs. If there are points in the system where the water supply is connected to a source of contamination during such an event – like a hose submerged in a pool or a pesticide sprayer attached to a garden hose – contaminants can be syphoned back into the drinking water supply.

These backflow events are not common, but when they do occur, they can pose significant risks to public health due to the potential for water contamination, hence the need for backflow prevention devices.

When is a Backflow Prevention Device Required?

A backflow prevention device is required under the following conditions:

Risk of Pollution

A backflow prevention device must be installed when the plumbing on premises has the potential to pollute either the water supply within the premises or the water supply provided by the water service provider. This is in accordance with AS/NZS 3500.1:2003, which specifies the appropriate backflow prevention device for particular applications.

Local Government Directive

Local governments have the authority to mandate the owner or occupier of premises to install, register, inspect, test, repair, or replace a backflow prevention device. This authority is invoked when the local government reasonably believes that the plumbing on the premises poses a risk of polluting the water supply.

Inspection and Testing

Local governments may, at any time, require the owner of a backflow prevention device to have the device inspected, tested, repaired, or replaced by a licensed person who is authorised to conduct such work. Following an inspection or test, the licensed person must provide the local government with written results within 10 business days.

Testable Devices

For testable backflow prevention devices, local government approval is necessary before installation. Local governments are required to implement and maintain a program for the registration, maintenance, and testing of these devices within their jurisdiction.

An owner of an installed testable backflow prevention device must fulfil two key responsibilities:

a. Register the device with the local government, thereby allowing for the monitoring of these critical devices.

b. Ensure that the device is inspected or tested for operational functionality at least once each year by a person who is licensed to perform this work. This regular testing is critical to ensuring that the device functions as intended and provides the necessary protection against water contamination. Contact us today if you live on the Gold Coast and need your backflow prevention device tested!

How Does Backflow Prevention Device Testing Work?

Backflow testing is a critical process that ensures your device is working as it should. During this test, a licensed and accredited backflow prevention plumber conducts a thorough inspection of the device, confirming that it is operating effectively to protect against water contamination. The process involves the following steps.

Preparation

Initially, the plumber will turn off the downstream shut-off valve in the system. After waiting a few minutes for the system to stabilise, they proceed to the testing phase.

Pressure Testing

The plumber uses a specialised backflow testing kit to measure the pressure in the system. This test is crucial, as it ensures that the pressure within the system is at the appropriate level, indicating that the device is functioning as it should.

Device Inspection

The plumber inspects the physical condition of the backflow prevention device, checking for wear, damage, or any other signs that the device may not be operating optimally.

Risk Assessment and Frequency of Testing

A hazard assessment is conducted by the installation plumber to establish the risk level of the property. Properties are categorised into high, medium, or low hazard ratings based on potential risks associated with their water supply systems.

For instance, high hazard properties are those that could pose a potential threat to human life, whereas low hazard properties are those that are generally a nuisance but do not endanger health or wellbeing.

Properties with a high or medium hazard rating must have their backflow devices tested after installation and then annually thereafter. In contrast, low hazard properties are usually fitted with a non-testable backflow device. Many smaller meters (20 or 25 mm) are fitted with a backflow prevention device designed for low-risk use.

Reporting

A licensed person who inspects or tests a testable backflow prevention device must submit the written results of the inspection or test to the local government in the approved form (Form 9) within 10 business days following the inspection or testing of the device.

Maintaining Compliance

For certain properties or situations, such as construction sites, emergency sprinkler or fire service systems, swimming pools, manufacturing facilities, and restaurants with grease traps, the installation of a backflow prevention device is a requirement. Regular testing and maintenance of these devices are mandated to ensure continued compliance with local regulations and safety standards.

Removing or replacing a device

A plumber will notify you if you need to remove or replace a backflow prevention device. This is how the process works:

Initiating the Process

A licensed plumbing contractor is responsible for initiating the removal or replacement of a device.

Notification and Documentation

The contractor must submit a Form 4 to the Queensland Building and Construction Commission (QBCC), which serves as a notice of the work undertaken.

Testing and Reporting

After the device has been removed or replaced, the contractor must complete and submit a Form 9 test report, documenting the condition and functionality of the newly installed device or confirming the successful removal of the old one.

Registration and Fees

The contractor is also required to submit a registration fee for each device to the local Council, along with the completed Form 9 test report. This fee is $73 a year per device.

Council Audits

The Council may conduct audits of device removals performed under a Form 4 to confirm that the hazard requiring the device replacement has been mitigated and is no longer present after the device’s removal.

Contact DCM Plumbing for Your Backflow Testing Needs Today

Backflow prevention devices play a pivotal role in safeguarding our water supply, acting as silent sentinels that protect us from potential contamination. Whether you are a homeowner, business operator, or property manager, staying vigilant about the installation, testing, and maintenance of these devices is a paramount responsibility. Remember to consult with a licensed backflow prevention plumber like DCM Plumbing to ensure that your property remains in compliance with local regulations and that our water remains pure and safe for all to use. Contact us today to find out how we can help.